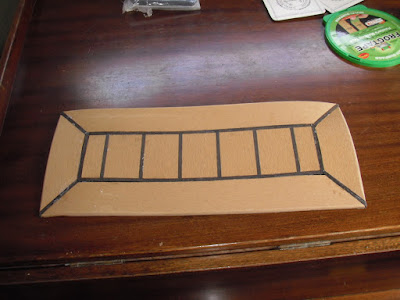

Drawer box with ply bottom

The next stage was to epoxy in a piece of hardwood across the opening this has two functions one to support the mounting for the drawer and the second to provide a mounting for the door catches once this was clamped up waiting for the epoxy to cure I filled in the cut out at the bottom of the opening using an offcut of GRP flat bar which was left over from a previous project, I have lots of offcuts of various materials and just occasionally they can be useful. The piece of bar was secured with some thickened epoxy and clamped in place.

Opening showing cut out at the bottom

Once the epoxy had cured I reinforced the hardwood with some woven mat strips and epoxy and the infill piece at the bottom was reinforced at the back with some chopped strand mat and epoxy. Once the epoxy had cured I cleaned up the GRP work and sanded the front face of the infill piece until it was flush the whole of the front of this moulding will be finished with a couple more coats of gelcoat this will also cover some areas that I had sanded through previously when I re coated the whole galley moulding.

Infill piece after sanding

I spent the rest of the day today making up the two side pieces which will support the drawer runners the WBP ply that I used has some voids in it so I have epoxied the raw edges and worked some thickened epoxy into the couple of voids that have shown up.

Two side pieces after epoxying the edges

This weekends homework job is to make up the rest of the woodwork the aim is to get the drawer and the dummy drawer front in place and then line up the doors to them as the drawer fronts will be the most difficult to align and fit.