I started this week by taking off the sails and the spray hood ready for lifting out on Wednesday, as I had an appointment with the coronary rehab team on Wednesday the plan was to move the boat round to the lift out berth on Tuesday afternoon. Once the berth was clear I fired up the engine and tried to get the stern to swing to starboard using the prop walk, however there was quite a stiff southerly blowing which was causing the stern to swing to port and the prop walk would not overcome this. I think that the problem is that New Morning only has a 12"x7" propeller as the engine has a 1:1 gearbox great for reducing the drag when sailing but just when prop walk might be useful its not there. In the end I had to go down the creek to a wider part and turn round, travel half a mile to cover 50 yards. I went over to Conyer today to find New Morning lifted out, pressure washed and sitting in a cradle so I got on with cleaning and stowing the fenders and stowing the mooring lines before conducting an inspection of the hull below the waterline, the first time I had seen it in over two years, it all looked pretty good apart from the brown east coast mud deposits which are like concrete. The keel looks good with no rust showing, it had a good dose of rust converter and two coats of underwater primer before anti fouling.

Friday, 23 October 2020

Lift out

Friday, 16 October 2020

Went sailing today

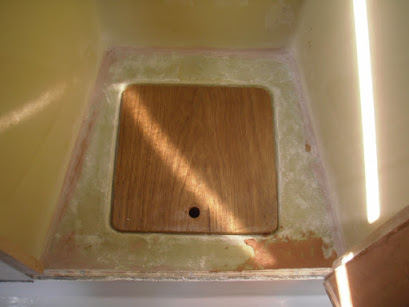

I started this week by having another look at the wind instruments, I checked the continuity of the cables as far as the connection box in the heads, there seems to be no problem up to this point it looks as though the problem is either in the mast or at the masthead but I am not taking it down just for that. I finished sanding the forward cabin sole it is just needing the final coat of flocoat. With the lift out programmed for next Wednesday I decided to go for a final sail, with a Northerly 2 or 3 it was not too bad although some sunshine would have been been welcome.

Friday, 9 October 2020

Short post this week

I have done a little more sanding to the forward cabin sole however I am suffering from a bit of a low boredom threshold with sanding so I decided to fix an outstanding issue with the engine stop cable. Before I got the engine running I had replaced the original engine stop cable with a new one, the original cable was a bowden cable and it was getting pretty frayed, the new one is a solid Morse type cable but it did not have the usual ferrule at the end of the outer sheath and while the engine stop function worked perfectly well but when pushing the knob back in to reset the stop all that happened was that the outer sheath moved so the stop lever had to be reset by hand before restarting the engine, this all worked OK in fact it was probably a good way of immobilising the engine provided that you remembered to do the reset. On further investigation I found that the stop lever return spring was too long so that even in the stop position there was insufficient tension in the spring to return the lever. I started by removing the spring and cutting about three-quarters of an inch off it before forming a new eye on the end. Replacing the spring was a bit tricky as it is behind the fuel rack return spring but after some perseverance I managed to refit it.

Friday, 2 October 2020

Back to sanding

Not a lot to write about this week I am afraid I was hoping that I would be able to get out into the Swale for a couple of hours at least once this week but the weather has been atrocious on the days that I had available such is life. The first task this week was to finish applying the varnish to the the shelf etc for the bookshelf behind the dinette seat back.

Friday, 25 September 2020

Light bulb moment

While I was in the shower contemplating the meaning of life I had a light bulb moment or should that have been a Homer Simpson 'doh' moment, the reason for the need to swap over the autopilot motor power leads had nothing to do with the motor having been replaced but the fact that the tiller that it operates on is mounted aft of the rudder stock so that the actuator needs to move in the opposite direction to give the correct rudder movement.

I started this week by making the shelf for the space behind the dinette and also a cover to go down at the bottom of the space which has an opening into the calorifier space, these now require varnishing which I have started and will add further coats next week. I then went on to clean up the bulkhead inside the space it had previously been lined with something possibly the same textured vinyl that was used on the remainder of the saloon bulkheads, the adhesive appeared to possibly be some form of latex which scraped off fairly easily. I gave the bulkhead a sanding and used some spray contact adhesive to secure a piece of the same grey van lining carpet that I had used for the rest of the headlining.

Friday, 18 September 2020

Autopilot

The aim this week was to finish tidying the wiring in the aft cabin locker the cabling to the autopilot actuator from the course computer included a chocolate block connector which i wanted to get rid of so I removed the actuator with the intention of renewing all the cables, however the cables to the motor and the clutch were connected directly to these items rather than to a terminal block and as I didn't want to go that far I removed the chocolate block connector and made a soldered connection for the extension cables these connections were wrapped in self amalgamating tape and the whole lot wrapped with spiral wrapping. The problem came when trying to replace the actuator, it is secured with a pin which is retained by a couple of 'R' clips but this is out of sight round the corner so it had to be done by feel, a bit of a struggle. I reconnected the cables and switched the autopilot on to test it and the rudder moved full travel in the opposite direction to that instructed, so after checking that all the cables were correctly connected to the course computer I consulted the manual which covered this very fault the instruction was to swap the two wires for the motor drive over which I did and it now works perfectly. The terminals in the course computer are all colour coded and they had all been correctly connected the only thing that I can think of is that the motor has been changed in the past I don't know but it works.

Friday, 11 September 2020

Loose ends

This week I have been tying up a few more loose ends I started on Monday with replacing some sea water hose elbows on the engine, when I put the engine back together I obtained a hose connection kit from Parts 4 Engines basically a bag of short pieces of hose of the various sizes required but the engine has three hose elbows which unfortunately did not come as part of the kit so in order to get the engine running I reused the old ones. Judging from the paint remaining on them these elbows were the originals fitted to the engine when it was manufactured in 1988 and while not in tip top condition they did serve a purpose. In the meantime I had purchased some new silicone hose elbows with the intention of replacing the originals but best laid plans and all that it was not until I was looking round the engine last week that I realised that the original elbows were well past their sell by date, touch them and they left a black stain on the hands, they had perished. The new elbows just required to be cut to size and pushed on and secured with 'Jubilee' clips

Friday, 4 September 2020

Housekeeping and some sailing

I have decided to leave the sanding of the forward cabin sole for a rainy day the main aim this week was to finish the internal clean and then start externally. I began by cleaning out the wet locker in the heads which was pretty grotty after sanding the sole, the interior is now looking fairly presentable. On Wednesday I went for a brief sail along the Swale as far as Milton Creek this was the first time out since I came out of hospital and so I was using parts of me that I hadn't used for some time. Basically most of my exercise regime has been walking whereas sailing involves a lot of pulling fortunately the weather was benign and the wind direction such that it was one tack out and one back usually with the predominant south westerly one way can involve a lot of tacking. Anyway all went well but I knew that I had done something a bit different. Today the plan was to clean up the exterior she was beginning to get that green colour that comes with external neglect so I set too with the hose and a scrubber, I use a 'Tough Scrub' available from Lakeland it is basically a foam pad with what I think is stainless steel wire anyway they are most effective in removing the muck and that lichen type growth that seems to have an affection for things fibreglass. My apologies for the lack of photographs but we all know what boats that require a good scrub get to look like every boatyard has a few lurking at the back of the yard. That is it for this week I hope to have something a bit more interesting to report next week.