Friday, 21 December 2018

Friday, 14 December 2018

More doors

Last weekend I managed to sand the front of doors and drawer front panel for the galley and then put on coat of primer/undercoat followed by the first coat of gloss I also cut out the doors for the heads locker and the steering gear compartment in the aft cabin.

The first job on Monday morning was to set up the doors in the heads and the aft cabin so that I could mark out the finger holes for the door catches, these were then cut out with a 38mm hole saw.

The first job on Monday morning was to set up the doors in the heads and the aft cabin so that I could mark out the finger holes for the door catches, these were then cut out with a 38mm hole saw.

Heads

Aft cabin

Once I had cut out the holes in the doors I went on to epoxy wooden blocks to the mouldings to provide a mount for the fixed part of the door/drawer catches, the mount for the galley door catches are simply screwed to the limber cross member.

Heads locker showing mounting for the door catch

From Wednesday on wards the weather has been far too cold for work involving glue and paint so work on the doors has come to a temporary halt, hopefully it will be warm enough next week to proceed with this project as the doors are a bit of a drawn out job requiring some filler in places and several coats of paint on each side plus wood stain and varnish for the trim.

To round off the week I spent some time fairing the thickened epoxy filler which I had applied to various holes in the heads sole moulding I had filled these holes some time ago finishing had not been a priority job but as the weather had effectively stopped work I decided to get this job out of the way.

Heads sole cleaned up

I am not sure what I will finally do with the heads sole moulding I had thought about re gelcoating but as there will be a shower in there a shiny gelcoat finish will be a bit slippery just add soap, the cover for the shower sump also needs some attention as the current finish is peeling off/discoloured.

Friday, 7 December 2018

Galley fit out

This week has been spent working inside as the weather for the most part was forecast to be wet and windy I started be assembling the supports for the drawer by attaching a couple of wooden brackets to the forward bulkhead I had made both of them parallel but as is usual with this boat nothing is straight, flat, or level etc. Too get the first side to sit square I had to taper them both I guess that most boats are the same.

Drawer support brackets

Once the support brackets were in place I fitted the drawer runners to the two side pieces and then secured them in place, the aft piece is secured to the stiffener, that I had previously fitted to stiffen up the original moulding, by a corner block I probably could have glassed these two pieces to the underside of the galley moulding but there would not be a lot of room to work and in any case if I can avoid glass work overhead then I will. A further brace was fitted at the inboard end of the aft piece to stiffen up the assembly.

Both side pieces in place

The drawer box was then slid into place it works very freely being on rollers it is probably a bit too free for a boat only time will tell.

Drawer box in place

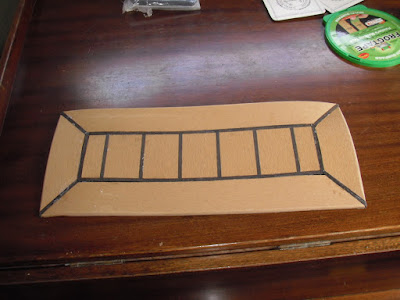

I have also cut out the plywood for the two doors and the drawer front also a dummy drawer front to cover the opening in way of the sink and today I set them up so that I could position the holes for the catches aka finger breakers I believe.

Drawer front

Doors

These parts will be painted white with a varnished hockey stick moulding around the edge to cover the raw plywood, the catches came with a ring to fit in the finger hole to tidy things up. The completion of these parts and the manufacture of the doors for the heads locker and the aft cabin steering gear space will be the next homework job, the plan is to make them all in the same manner.

Friday, 30 November 2018

Inclement weather again

The weather at the beginning of this week was horrible, wet and windy, but as the plan was to get on with the internal fit out it was not going to cause a problem. Over last weekend I made a new bottom for the cutlery drawer box from some 12mm WBP ply and gave it a couple of coats of varnish to seal the wood this enabled me to be able to assemble the drawer box. I had no idea how the original drawer was installed all I had was an empty space so this was going to be a make it up as you go along job and the drawer box would be the starting point.

Drawer box with ply bottom

The next stage was to epoxy in a piece of hardwood across the opening this has two functions one to support the mounting for the drawer and the second to provide a mounting for the door catches once this was clamped up waiting for the epoxy to cure I filled in the cut out at the bottom of the opening using an offcut of GRP flat bar which was left over from a previous project, I have lots of offcuts of various materials and just occasionally they can be useful. The piece of bar was secured with some thickened epoxy and clamped in place.

Opening showing cut out at the bottom

Once the epoxy had cured I reinforced the hardwood with some woven mat strips and epoxy and the infill piece at the bottom was reinforced at the back with some chopped strand mat and epoxy. Once the epoxy had cured I cleaned up the GRP work and sanded the front face of the infill piece until it was flush the whole of the front of this moulding will be finished with a couple more coats of gelcoat this will also cover some areas that I had sanded through previously when I re coated the whole galley moulding.

Infill piece after sanding

I spent the rest of the day today making up the two side pieces which will support the drawer runners the WBP ply that I used has some voids in it so I have epoxied the raw edges and worked some thickened epoxy into the couple of voids that have shown up.

Two side pieces after epoxying the edges

This weekends homework job is to make up the rest of the woodwork the aim is to get the drawer and the dummy drawer front in place and then line up the doors to them as the drawer fronts will be the most difficult to align and fit.

Friday, 23 November 2018

More paint

The weather was pretty cold and damp for the start of the week certainly not fit for external painting so I spent some time inside looking at the galley lockers under the sink at present there is just a gaping hole.

The first item is a cutlery drawer I didn't particularly want to build a drawer from scratch so after looking around I found a basic drawer box on the B&Q website they are supposed to be manufactured from stainless steel but as they are powder coated I can't tell but for ten quid can't complain. The bottom of the drawer box is best chipboard but this will be easy to replace with a piece of 12mm WBP ply.

Under the sink

The first item is a cutlery drawer I didn't particularly want to build a drawer from scratch so after looking around I found a basic drawer box on the B&Q website they are supposed to be manufactured from stainless steel but as they are powder coated I can't tell but for ten quid can't complain. The bottom of the drawer box is best chipboard but this will be easy to replace with a piece of 12mm WBP ply.

B&Q drawer box

The front of the drawer will be matched to the locker doors I was thinking of using the same solid laminate that I used for the worktops but it is expensive and I would have a lot left over so I am thinking of using plywood painted white with a varnished hardwood edging.

On Wednesday the weather was dry enough to finish sanding the starboard side cockpit benches much too cold and damp for painting but at least a little progress was made.

Today the weather was dry and warm enough for painting and to make sure I ran the engine for a while to warm things up a bit. After masking up the starboard side cockpit benches and the aft cabin roof I gave both areas a good coat of non slip deck paint. The rest of the decks require repainting but that will probably have to wait until the spring.

Aft cabin roof

Cockpit benches looking much smarter

Friday, 16 November 2018

Finally got some paint on

The weather was looking favourable this week for painting the tops of the cockpit benches with non slip deck paint, as the instructions recommend 3 or 4 days before walking on the newly applied paint I decided to do the job in two halves. I began by sanding the port side benches together with the aft cabin roof and the two areas under the spray hood and after washing down left the whole lot to dry.

The first thing Wednesday I gave all the areas a wipe down with a damp cloth to remove any dirt and left it all to dry in the bright sunshine. Once everything was dry I masked up the port benches and the two areas under the spray hood this took quite some time especially as all the corners required a radius to be cut in the masking tape I used a Stanley knife and cut round some new Jubilee clips as they were easily adjusted to the required radius. Once the masking was complete I applied a good coat of International deck paint using a brush to stipple it on and then while the paint was still wet I removed the masking tape.

It reminds me of the boys manning the mast at the Royal Navy training base at Shotley if you look closely there is a 'button' bird sitting on the masthead lamp.

The first thing Wednesday I gave all the areas a wipe down with a damp cloth to remove any dirt and left it all to dry in the bright sunshine. Once everything was dry I masked up the port benches and the two areas under the spray hood this took quite some time especially as all the corners required a radius to be cut in the masking tape I used a Stanley knife and cut round some new Jubilee clips as they were easily adjusted to the required radius. Once the masking was complete I applied a good coat of International deck paint using a brush to stipple it on and then while the paint was still wet I removed the masking tape.

Port side cockpit

Today I had planned to sand the starboard side cockpit benches and the various bits of gelcoat repair on that side so that I would be ready to mask up and paint on Monday however best laid plans and all that today dawned miserable, wet and foggy and remained so all day so I had to be content with pottering around inside, I removed the inboard folding leaf from the saloon table as it was not really a lot of use and always seemed to be in the way. I removed the fiddle rail and transferred it to the table top in the same way as I had previously treated the outboard side of the table. I spent the rest of the day having a bit of a clean up and thinking about various locker doors in the heads. saloon and aft cabin I am thinking of making them from the same solid laminate that I used for the worktops in these areas however to buy a piece large enough to do all the doors and a cutlery draws will leave quite a substantial piece left over so at the moment the jury is still out on this. I was just packing up for the day when I noticed this group of starlings on the rigging of a boat on the other side of the creek I am glad it's not my boat underneath them.

It reminds me of the boys manning the mast at the Royal Navy training base at Shotley if you look closely there is a 'button' bird sitting on the masthead lamp.

Friday, 9 November 2018

Plastic teak

This will be a bit of a short post as I did not get the plastic teak panels made up over last weekend as a garden project got in the way however on Monday morning I made a start with the panel for the aft companionway entrance.this was followed up by the forward panel on Wednesday. The fake teak is manufactured from Upvc I have been using 50mm wide tongue and groove strip which has the caulking moulded on. I started with the centre section which is glued together with solvent cement.

Centre section for aft companionway

The centre section was then cut to width. The caulking was then added all around the centre section using a top hat section material.

Caulking material

To form the outside edge pieces I removed the caulking and the tongue from some more of the strip and sanded a radius on the outside edge, the material is available with a rounded edge and without the caulking but as I was using existing stock it was not worth buying any for the small amount needed., The edging was then glued in place with the solvent cement.

Completed aft companionway panel

The completed panel does not lay flat as the pieces were cut from a roll I did put some weight on it and left it for a while and it does eventually flatten out but if left long enough it seems to have a bit of a memory and it will try and return to the original curve. After giving both areas a good sanding with some 40 grit paper to give the adhesive a bit of a key the back of the panels and the GRP were given a good clean with acetone and the panels glued down with Sabatak, black sticky stuff supplied with the fake teak, and then weighed down to allow the adhesive to cure. I used masking tape to prevent the adhesive from spreading beyond the panels.

Aft companionway

Aft companionway

On Monday morning I shall cut round the panels with a Stanley knife and remove the masking tape. It doesn't show in the photographs but the aft panel is made from Tek Dek the forward panel is Dek King they are almost the same bar the dovetail slots on the back which are slightly different sizes also the colour is slightly different as the panels are not adjacent it's not enough to show and after they have been weathered.

Friday, 2 November 2018

Winter on the way

The first job this week was to put some antifreeze in the engine just as a precaution probably not strictly necessary yet as the boat is still afloat and the sea water nowhere near freezing point yet but now that I have sorted all the minor leaks I may as well make use of its anti corrosion properties as well.

I dug the spray hood out of the garage and fitted it to the frame it has seen very much better days the fabric has gone hard and crispy plus it does not fit very well also it has split in way of the main frame tube. After playing around with it for some time I managed to get a reasonable fit but it is definitely a candidate for replacement. The stainless steel frame however is in reasonable condition and will be reused.

I dug the spray hood out of the garage and fitted it to the frame it has seen very much better days the fabric has gone hard and crispy plus it does not fit very well also it has split in way of the main frame tube. After playing around with it for some time I managed to get a reasonable fit but it is definitely a candidate for replacement. The stainless steel frame however is in reasonable condition and will be reused.

Spray hood

I have spent the rest of this week working on sanding the various gelcoat repairs. I have been giving some thought to the non slip areas of the cockpit which I had decided to paint with non slip paint however the two companionway entrance areas will be subject to concentrated wear which will probably mean that the paint will wear through fairly quickly I had been considering Treadmaster again however I have some plastic teak left over from work on previous boats so this weekends homework job will be to make up two panels for these areas.

Saloon companionway

Aft cabin companionway

The above photographs show where the original Treadmaster was glued the plastic teak panels will be of a similar size.

Friday, 26 October 2018

Gone sailing again

I began the week by repairing a few more areas of damaged gelcoat around the cockpit and deck there are no photographs as it was only small areas which required attention it was just a matter of opening them out giving them a good sanding, cleaning with acetone and then refilling with gelcoat as previously detailed.

As the weather was looking reasonable for the remainder of the week, well at least until Friday I decided to go sailing again to make the most of what was left of the fine weather. The plan was to leave on Wednesday's high water which was around 13.00, which would mean I would be able to get away about 11.30, and sail across the Thames estuary up to the river Colne and anchor up near Pyfleet for the night then spend the day sailing the area before returning home today. The trip up there was uneventful with the forecast force 3 or 4 nowhere to be seen so it was a matter of motor sailing most of the way with only a couple of brief interludes of sailing. The route was the same as the previous trip just the destination slightly changed I did not fancy another sleepless night rolling around off Jaywick.

As the weather was looking reasonable for the remainder of the week, well at least until Friday I decided to go sailing again to make the most of what was left of the fine weather. The plan was to leave on Wednesday's high water which was around 13.00, which would mean I would be able to get away about 11.30, and sail across the Thames estuary up to the river Colne and anchor up near Pyfleet for the night then spend the day sailing the area before returning home today. The trip up there was uneventful with the forecast force 3 or 4 nowhere to be seen so it was a matter of motor sailing most of the way with only a couple of brief interludes of sailing. The route was the same as the previous trip just the destination slightly changed I did not fancy another sleepless night rolling around off Jaywick.

Red Sand forts again

The forts are or were the subject of a restoration project under the title of project Red Sand I am not sure whether of not it is still active, they have a website but it has not been updated for some time there is plenty of information on these wartime relics on t'interweb. I arrived in the Colne around 19.00 and met up with a colleague who had sailed up the day before.

Sunset over Essex

Friday's weather forecast was not looking good for the return trip and with the weekend weather also looking poor after a brief discussion we decided to return home on Thursday morning. We upped anchor at 05.30 to make the best of the ebb tide as far as the Swin Spitway so that once out into Middle Deep the tide should be on the turn and then the flood tide would carry us all the way home. The forecast north westerly or westerly 3 or 4 certainly arrived on cue and with the help of the tide we had a spirited sail all the way home arriving in Conyer Creek about 12.00. On crossing the shipping channel to the Red Sand forts every other ship on the planet seemed to turn up in fact I have never seen it so busy but however I managed to get across safely with only a brief delay while passing astern of a large car carrier.

Today has been a clean and tidy up day with the aim for next week being to get the work out on deck moved forward.

Friday, 19 October 2018

Cockpit

Back to serious work this week although there is not a great deal to show for the effort I started off by opening up the stress cracks in the radius between the cockpit benches and the side of the cockpit this was followed up by a good sanding and a wash down with acetone to clean up the surface and provide a key for a coat of gelcoat which was followed up once it had started to gel by a coat of gelcoat with some wax in styrene added, aka flocoat. The wax in styrene rises to the surface to exclude the air which allows the gelcoat to fully cure. There were not many stress cracks but there were also some chipped and flaking in places so I have gone right the way round the cockpit in the hope that the finished job will look a bit less patchy.

Starboard side after applying gelcoat

I started today by sanding back the gelcoat on the port side with wet and dry sandpaper as can be seen I have not tried to colour match the new gelcoat with the old I will just fair it in and leave it to weather.

Port side after sanding the new gelcoat

The difference in colour between the original gelcoat and the new doesn't look so bad in the photograph now that it has been tidied up but it does show up more in the flesh. That is about it for this week next week the plan is to finish fairing the new gelcoat so that I can then get on with painting the non slip areas.

Friday, 12 October 2018

Quiet week

There is not a lot to show for this weeks efforts, I started on Monday morning by running the engine up to full operating temperature to check on the water leak which I had previously repaired, all was well. I had found a piece of the galley worktop fiddle rail in the big bag of wooden bits that I have at home and since building the galley lockers it was now redundant so I decided to use it to finish off the rack behind the cooker so it was cut to length and given three coats of varnish over the week.

When I reassembled the engine I purchased a kit of various rubber hose connections from Parts 4 Engines unfortunately there are three elbows which were not included in the kit so one of this weeks jobs was to measure up for said elbows so that I can replace the existing which are getting past it, I am going to use silicon rubber elbows from Hyphose.

On Wednesday the weather was warm and sunny with a south easterly 3 or 4 which was too good to waste so went for a sail down the Swale towards Harty and back there were quite a few like minded souls out there just like mid summer.

Had a bit of a late start today but I did manage to fit the piece of fiddle rail on the rack behind the cooker.

When I reassembled the engine I purchased a kit of various rubber hose connections from Parts 4 Engines unfortunately there are three elbows which were not included in the kit so one of this weeks jobs was to measure up for said elbows so that I can replace the existing which are getting past it, I am going to use silicon rubber elbows from Hyphose.

On Wednesday the weather was warm and sunny with a south easterly 3 or 4 which was too good to waste so went for a sail down the Swale towards Harty and back there were quite a few like minded souls out there just like mid summer.

Had a bit of a late start today but I did manage to fit the piece of fiddle rail on the rack behind the cooker.

Fiddle rail added to rack

After returning to the marina on Wednesday I noticed a slight weep on the union for the fuel return to the tank which is on the top of the secondary fuel filter so to finish off a rather lazy week I fitted a new rubber olive in the union.

Fuel filter with return fuel pipe union

Next week I must bite the bullet and get on with some serious work while the weather is being kind, the aim will be to get the non slip areas of the deck painted and repair some of the minor areas of damage in the gelcoat.

Friday, 5 October 2018

Starter solenoid

The first job on Monday morning was to remove the defective starter solenoid this was a fairly easy job I removed the mounting plate from the engine as I was sure that the new solenoid mounting bolts would not coincide with the old ones.

Defective starter solenoid

First thing on Wednesday I made a start on the water leak, to reach the offending fitting required the removal of the heat exchanger and the aft end engine lifting eye. Once I had removed the elbow and the valve the cause of the problem immediately became obvious, the elbow is effectively a right angle tap connector which had been fitted into a 15mm compression fitting with a sealing washer, the washer had broken up leading to the leak. In any event the end of a 15mm compression fitting does not have sufficient area to support a sealing washer so I cut off the flange and found that a 15mm brass olive was a good fit on the remaining part of the elbow, I hope that the description is clear I should have included some more photographs however it all went back together and was fully tightened so that there was no movement in the fitting it had been quite loose as the sealing washer had disintegrated. I spent the rest of the day replacing the heat exchanger and after refilling the cooling system with water I had a good look round, everything appears to be tight. When there is sufficient water in the creek, probably next Monday, I shall run the engine for a proper test of the repair.

The offending elbow can just be seen hiding behind no4 injector

I ordered a new starter solenoid from Parts 4 Engines on Tuesday evening and it arrived on Thursday at lunchtime. As expected I had to drill some new holes in the mounting plate for the bolts to secure the solenoid. I started this morning by bolting the solenoid to the mounting plate before re securing the whole lot to the engine then once this was done I began to connect the various cables. Some of the connections were beginning to look somewhat frayed so I re terminated most of the smaller control cables for the starter solenoid and the engine pre heater which operates through a relay also mounted on the same plate, the main starter cable terminations were in good order so these were just re connected.

New starter solenoid with pre heater relay above

Once everything had been re connected I turned the key and the starter motor immediately engaged and turned the engine over job done.

Monday, 1 October 2018

Shakedown

This post is a little late as I finally got to do a shakedown trip, up to now apart from the delivery from Queenborough round to Conyer I had only done two brief trips out on the tide in the Swale and I really wanted to give everything a more thorough test.

I started the week last Monday by fitting the rack for the storage containers behind the cooker, I had made the parts some time ago and had been looking for some suitable containers for tea, coffee etc. Now I know that may be the wrong way to do a job like this but a couple of weeks ago I found exactly the containers for the job in Sainsburys.

I started the week last Monday by fitting the rack for the storage containers behind the cooker, I had made the parts some time ago and had been looking for some suitable containers for tea, coffee etc. Now I know that may be the wrong way to do a job like this but a couple of weeks ago I found exactly the containers for the job in Sainsburys.

Rack for storage containers

Getting back to the shakedown I left Conyer on the Wednesday afternoon high water and sailed in company with a friend up through the Swale, West Swin, Middle Deep and the Swin Spitway and anchored off Jaywick for the night unfortunately there was a bit of a swell rolling in which led to pretty sleepless night. Leaving Jaywick on Thursday morning we sailed around before anchoring for the night on the North side of the entrance to the River Blackwater where again the swell led to another uncomfortable night. After raising anchor on Friday morning we sailed over to Bradwell Marina for the night after a good shower, a couple of pints and some fish and chips a decent nights sleep ensued. In order to return home on Sunday making the best use of the tide we left Bradwell on Saturday afternoon and after sailing up the Blackwater to Osea Island we came back down and anchored in the River Colne off Brightlingsea where peaceful night ensued. Leaving the Colne at 07.00 with about three hours of the ebb to run so that once through the Swin Spitway we could take advantage of a favourable flood tide to carry us all the way home. With a westerly 3 or 4 forecast we had a cracking sail home even with the baggy mainsail in fact I had to slow right down passing Faversham as I would not be able to get into Conyer Creek until about 15.00 as I was going I would have been at the entrance to the creek about 14.00 with an hour to wait so the last couple of miles were run with the mainsail and the engine on tick over with the wind on the nose creeping along at about 2 knots.

Sailing down Middle Deep

Red Sand forts

All in all I am quite happy with the way the boat sails making a fairly effortless 7-8 knots much of the time, albeit with a favourable tide, all the various systems that I had installed worked perfectly. There were only a couple of minor niggles there has been a persistent water leak on the engine fresh water side which I thought I had cured but on further investigation in Bradwell I finally found it on the connection from the cylinder head to the calorifier coil which is very difficult to access however with the aid of a hammer and a screwdriver I managed to tighten it up to reduce the leak to a minimum in order to do a proper job I will have to remove the heat exchanger again. Then on leaving Bradwell turning the key to start the engine resulted in just an ominous click of the solenoid, on checking round it appeared that the main contacts were not making so the emergency starting tool was used, a screwdriver across the solenoid terminals, and with a few sparks the engine fired up immediately. The rest of this week will be spent sourcing and fitting a new solenoid and fixing the water leak once and for all.

Friday, 21 September 2018

Engine back up and runing

The first job on Monday was to replace the engine heat exchanger and then connect up the various hoses and then after checking round all the hose connections I filled the cooling system and checked round for any signs of leaks. The next job was to turn the engine over on the starter to complete the priming of the fuel system which was as far as I could go until there was enough water to run the engine. To finish off the day I did a bit more scraping the old Treadmaster adhesive from the cockpit benches.

On Wednesday morning I noticed that the domestic water pump was cutting in intermittently which it had never done before, other than when the taps were turned on, on further investigation I found a substantial amount of water in the saloon bilge which when put together with the pump cutting in indicated a leak in the domestic water system. After checking all the joints on the system I found the leak on the elbow for the calorifier relief valve and after removing the relief valve careful examination of the elbow showed a crack in the fitting.

Port side after scraping contact adhesive

On Wednesday morning I noticed that the domestic water pump was cutting in intermittently which it had never done before, other than when the taps were turned on, on further investigation I found a substantial amount of water in the saloon bilge which when put together with the pump cutting in indicated a leak in the domestic water system. After checking all the joints on the system I found the leak on the elbow for the calorifier relief valve and after removing the relief valve careful examination of the elbow showed a crack in the fitting.

Elbow showing crack

Searching through the odds and ends box I found replacement fitting which was duly fitted and hey presto the domestic water system is back to normal. Again to finish off the day I spent some more time scraping the cockpit benches.

First thing this morning, as the boat was afloat, I started the engine and gave it a good run to check the fuel system which appears to be all OK the idle speed required a minor adjustment to bring it up to the correct setting of 625 rpm. I did a bit more to the cockpit benches until rain stopped play so to finish up the day I came inside and did a further investigation into the wind instruments but to no avail it is a tad difficult without ant form of manual this will be a rainy day job as they are not particularly high on the outstanding job list. Now that the engine is sorted the plan is, weather permitting, to go sailing next week.

Subscribe to:

Comments (Atom)